InControl is a story of building a standards-based platform designed to scale from day one. We embraced Open Charge Point Protocol (OCPP), the industry standard for EV charger communication, and built an API-first architecture before "API-first" became a buzzword. What makes InControl special isn't just the technology so much as how we built it. The initial features were designed by and for our service department and technicians, the people who actually kept chargers running in the field. As the sole product manager for much of InControl's early development, I worked directly with customers like Cruise to understand their needs and rapidly launched features that transformed the platform. Through thousands of customer interactions, InControl evolved from an internal service tool into a comprehensive maintenance and management system with real-time monitoring interfaces, sophisticated reporting features, and tools built specifically for fleet managers and site managers.

The Beginning: A Vision for Intelligent Charging

When InCharge Energy first introduced InControl in the early days of the EV charging revolution, it was conceived as an operations platform for our own use — a sophisticated dashboard designed to monitor, manage, and optimize InCharge's own hardware deployments. Built on the foundation of real-time data analytics and remote diagnostics, InControl gave charge point operators unprecedented visibility into their charging infrastructure, enabling them to track uptime, handle service remotely, and respond to operational issues before they escalated into costly downtime.

But from the very beginning, the system's three dads (VP of Engineering Sergey Ahranovich, our CPO Krishna Vanka, and software architect Eugene Astapovich) understood that the future of charging infrastructure would be built on scalability and interoperability. Their vision was to create a platform that embraced open standards from day one, ensuring that InControl could communicate seamlessly with any compliant charging hardware, regardless of manufacturer.

This commitment to openness manifested in InControl's native support for OCPP 1.6-J, the industry standard protocol for charge point communication. As the protocol evolved, InControl evolved with it, subsequently adopting OCPP 2.0.1 to take advantage of enhanced security features, improved transaction handling, and more sophisticated device management capabilities. This standards-first approach meant that even in its earliest iterations, InControl was never proprietary in the traditional sense as it was always built to natively speak the language of the broader charging ecosystem.

Our committment to standards enabled us to create a brand-agnostic charging software, at least in theory. In practice, every charger interpreted the standards a little differently, requiring some manual onboarding to make sure we understood their dialect of the mother tongue OCPP. This then required us to build tooling to make the onboarding process smoother.

Built for Integration: The API-First Philosophy

Equally foundational to InControl's architecture was the decision to adopt an API-first development philosophy. Rather than building a monolithic platform with limited external connectivity, Ahranovich, Vanka, and Astapovich designed InControl as a composable system where every function, from charger monitoring to service dispatch to energy management, would be accessible through robust APIs. When I came on board, I led the drive to commercialize and expand the API for our customers. Today, a significant number of customers use our API for their own data warehousing, custom applications, and backend integrations.

This API-first approach wasn't simply good engineering practice; it was a strategic imperative that would prove invaluable as InControl evolved into a true Charger Maintenance & Management System. Our OEM partners, for example, use our API to populate their own dashboards, while microgrid integrators use our API to assist in managing energy flows and output to our chargers.

For partners integrating with InControl, the API-first approach delivers transformative advantages:

Seamless System Integration: Fleet management software, property management systems, energy management platforms, and billing systems can all connect directly to InControl's APIs, eliminating manual data entry and creating unified workflows.

Custom Application Development: Partners can build bespoke applications and interfaces tailored to their specific operational needs while leveraging InControl's backend infrastructure for all the heavy lifting—data processing, OCPP communication, diagnostic algorithms, and maintenance scheduling. This dramatically reduces development time and allows partners to focus on their unique value propositions rather than reinventing charging infrastructure management.

Real-Time Data Access: APIs provide programmatic access to live charging data, enabling partners to build real-time monitoring dashboards, trigger automated workflows based on specific events (charger faults, session completions, energy thresholds), and incorporate charging metrics into broader business intelligence platforms.

Flexible Deployment Models: Some partners want turnkey solutions; others want to embed charging management deep within their own platforms. The API-first architecture accommodates both approaches, allowing partners to consume as much or as little of InControl's functionality as their use case demands.

Future-Proof Scalability: As partners' businesses grow and their needs evolve, they can progressively adopt additional InControl capabilities through the same consistent API framework, without disruptive platform migrations or system overhauls.

Engineered for Scale: Cloud-Native Architecture

The third foundational decision that shaped InControl's trajectory was the commitment to a scalable, cloud-based architecture. From inception, the platform was designed to operate in distributed cloud environments, leveraging containerization, microservices, and elastic infrastructure to handle growth without degradation.

This architectural choice has proven prescient. Over the past several years, the number of chargers managed by InControl has increased nine-fold—a rate of growth that would cripple traditionally architected monolithic systems. Yet throughout this explosive expansion, InControl has maintained over 99.97% service uptime, a reliability threshold that many enterprise-grade platforms struggle to achieve even at static scale.

How does cloud-native architecture enable this seemingly paradoxical combination of dramatic growth and rock-solid reliability?

Elastic Scalability: Cloud infrastructure allows InControl to automatically provision additional computing resources during peak demand periods and scale back during quieter times. When a new customer brings hundreds of chargers onto the platform, the system seamlessly expands to accommodate the load without manual intervention or performance degradation for existing users.

Geographic Distribution: By operating across multiple data centers in different geographic regions, InControl eliminates single points of failure and ensures that regional outages or connectivity issues don't cascade into system-wide problems. Charger operators in California continue functioning normally even if a data center in Virginia experiences issues.

Microservices Independence: Breaking the platform into discrete, independently deployable microservices means that updates, patches, and new features can be rolled out to specific components without taking the entire system offline. A diagnostic algorithm enhancement or billing module update doesn't require system-wide downtime.

Automated Failover and Redundancy: Cloud-native design enables sophisticated disaster recovery mechanisms. If any component fails, traffic automatically routes to healthy instances. Database replicas ensure that no transaction data is lost, even in catastrophic failure scenarios.

Real-Time Monitoring and Self-Healing: The platform continuously monitors its own health, automatically detecting performance anomalies and initiating corrective actions before users experience any impact. This proactive approach to infrastructure management has been instrumental in maintaining exceptional uptime even as system complexity has increased.

The business impact of this architectural decision cannot be overstated. For charging operators, 99.9% uptime translates directly to revenue protection—fewer lost charging sessions, reduced customer frustration, and minimized emergency service calls. For InCharge Energy's partners integrating via API, it means they can confidently build mission-critical applications on InControl's infrastructure, knowing the platform will be there when their customers need it.

The Market Shift: Recognizing a Larger Need

As the EV charging landscape matured, InCharge Energy's service teams began noticing a pattern. Customers weren't operating homogeneous charging networks—they had inherited mixed fleets through acquisitions, expanded with different vendors to meet varying use cases, or simply needed to maintain legacy hardware alongside newer installations. Site owners and operators were juggling multiple management platforms, each with different interfaces, data formats, and maintenance protocols.

More critically, when chargers failed, the fragmented vendor landscape created operational nightmares. Different manufacturers meant different service protocols, disparate parts inventories, and varying response times. For businesses whose operations depended on charging availability—fleet depots, logistics hubs, multifamily properties, and public charging networks—this complexity translated directly into lost revenue and frustrated customers.

InCharge Energy's field service technicians were already being called to diagnose and repair competitive hardware, having built deep expertise across multiple charging platforms through years of hands-on experience. But rolling a truck every time there was a service call is cost prohibitive for customers besides the inevitable delay between when the call comes in and when the service takes place. The question emerged: Why couldn't InControl perform this function and provide remote diagnostics and service?

The Transformation: From Platform to Ecosystem

The transformation of InControl began with a fundamental shift in philosophy. Rather than viewing the platform as a value-add for InCharge hardware, the company recognized an opportunity to solve a universal pain point across the entire charging industry. The decision was made to evolve InControl into an agnostic Charge Maintenance & Management System—a unified platform capable of monitoring, managing, and maintaining charging infrastructure regardless of manufacturer.

This wasn't a simple rebrand. It required expanding the architectural foundation that Ahranovich, Vanka, and Astapovich had built:

Universal Integration Layer: The engineering team expanded the OCPP implementation to accommodate the quirks and variations in how different manufacturers interpret the standard, while also developing custom integrations for proprietary protocols. This allowed InControl to aggregate data from diverse hardware into a single, normalized data model.

Manufacturer-Agnostic Diagnostics: Drawing from InCharge's extensive service database, the platform incorporated diagnostic algorithms and fault codes from dozens of charging manufacturers, creating a universal troubleshooting engine that could identify issues across brand boundaries.

Comprehensive Service Management: This is where InControl truly transformed into a complete Charge Maintenance & Management System. The platform evolved to include sophisticated capabilities that go far beyond simple monitoring:

Service Call Tracking: Complete lifecycle management of service requests, from initial fault detection through technician dispatch, on-site resolution, and post-service verification. Every service interaction is documented, tracked, and analyzed to identify patterns and improve response protocols.

Preventative Maintenance Contracts and Visits: Structured management of ongoing maintenance agreements, automated scheduling of routine service visits, and compliance tracking to ensure contractual obligations are met. The system proactively schedules preventative maintenance based on manufacturer recommendations, usage patterns, and historical performance data.

Maintenance Mode: A critical operational feature that allows operators to temporarily take chargers offline for scheduled maintenance without triggering false alarms or skewing uptime metrics. Maintenance Mode ensures accurate reporting while giving service teams the flexibility to perform necessary work during optimal windows.

Warranty Tracking: Comprehensive warranty management across multiple manufacturers, tracking coverage periods, claim submissions, and parts replacement history. The system automatically flags warranty-eligible repairs, streamlines claim documentation, and ensures operators maximize their warranty benefits across diverse hardware portfolios.

Open Data Architecture: Recognizing that customers needed flexibility, InControl maintained its API-first philosophy, ensuring that all new maintenance and service features were fully accessible programmatically, allowing partners to build custom workflows and integrations around these capabilities.

Innovation in Intelligent Infrastructure: Patented Technologies

As InControl evolved to manage increasingly complex, multi-manufacturer charging environments, InCharge Energy invested heavily in solving novel technical challenges—work that has resulted in significant intellectual property assets.

The company has a patent pending for smart charging technology that optimizes power distribution across mixed-vendor charging installations. This innovation allows InControl to balance load dynamically based on real-time grid conditions, electricity pricing, vehicle requirements, and charger capabilities—regardless of manufacturer—delivering cost savings and grid stability benefits that would be impossible in vendor-siloed systems.

Additionally, InCharge Energy holds an issued patent for a transparent proxy architecture used in OCPP forwarding. This technology is crucial for enabling InControl to serve as a unified management layer while still allowing manufacturers' backend systems to receive necessary data for warranty validation and support purposes. The transparent proxy seamlessly forwards OCPP messages between chargers and multiple backend systems without creating conflicts or requiring complex dual-connection configurations, solving a persistent technical challenge that had limited multi-platform management capabilities.

These patented technologies aren't just technical achievements—they represent fundamental enablers of InControl's manufacturer-agnostic approach, providing capabilities that competitors using conventional architectures simply cannot replicate.

Human-Centered Design: Building Features Through Field Research

Product management in the EV charging industry requires more than roadmaps and feature specifications—it demands deep, firsthand understanding of how operators actually work. I spent extensive time in the field at customer charging sites, observing fleet managers, site technicians, and depot operators as they used InControl in their daily workflows. These field sessions weren't one-time exercises; they were an ongoing practice that fundamentally shaped the platform's evolution.

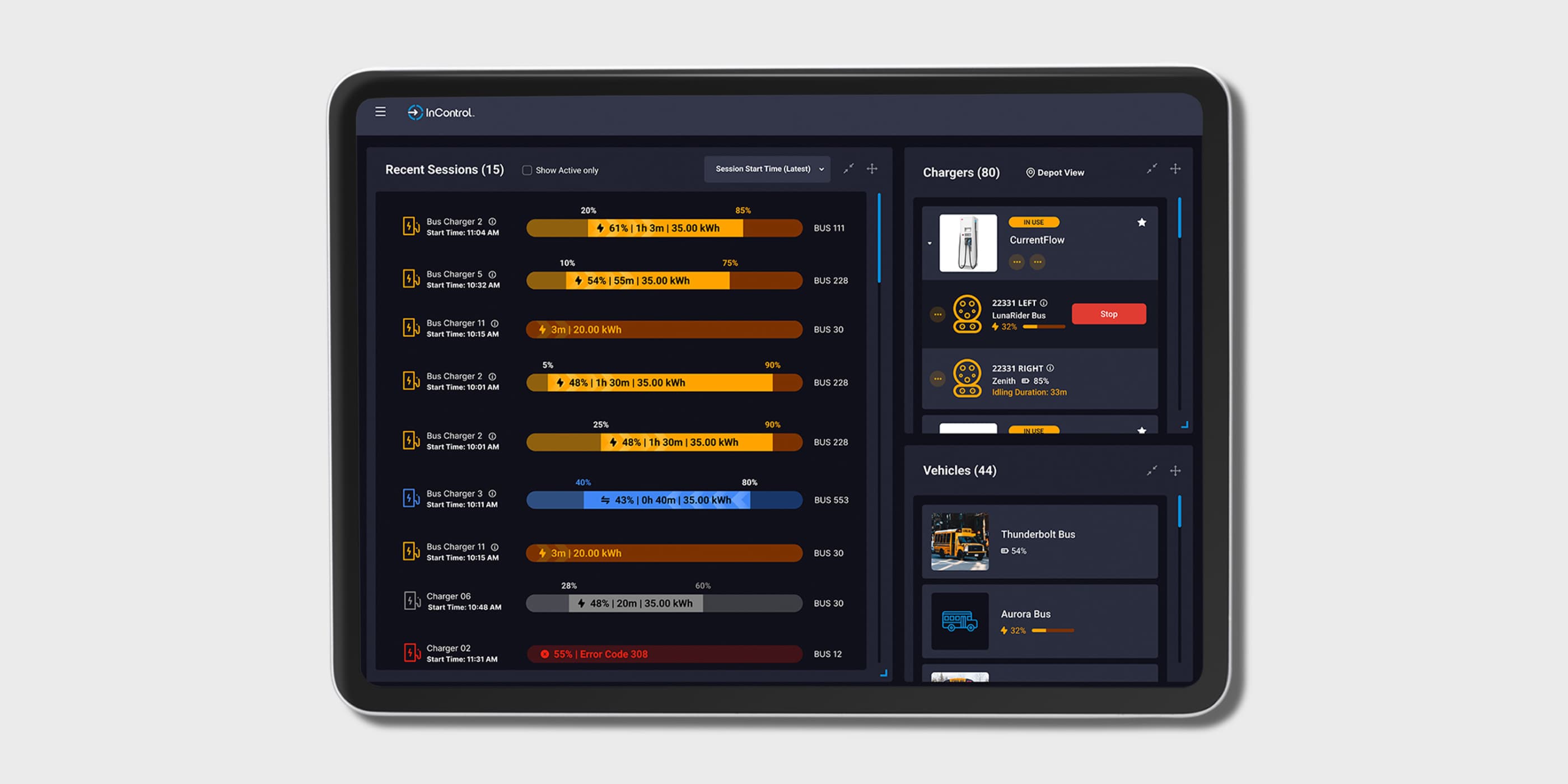

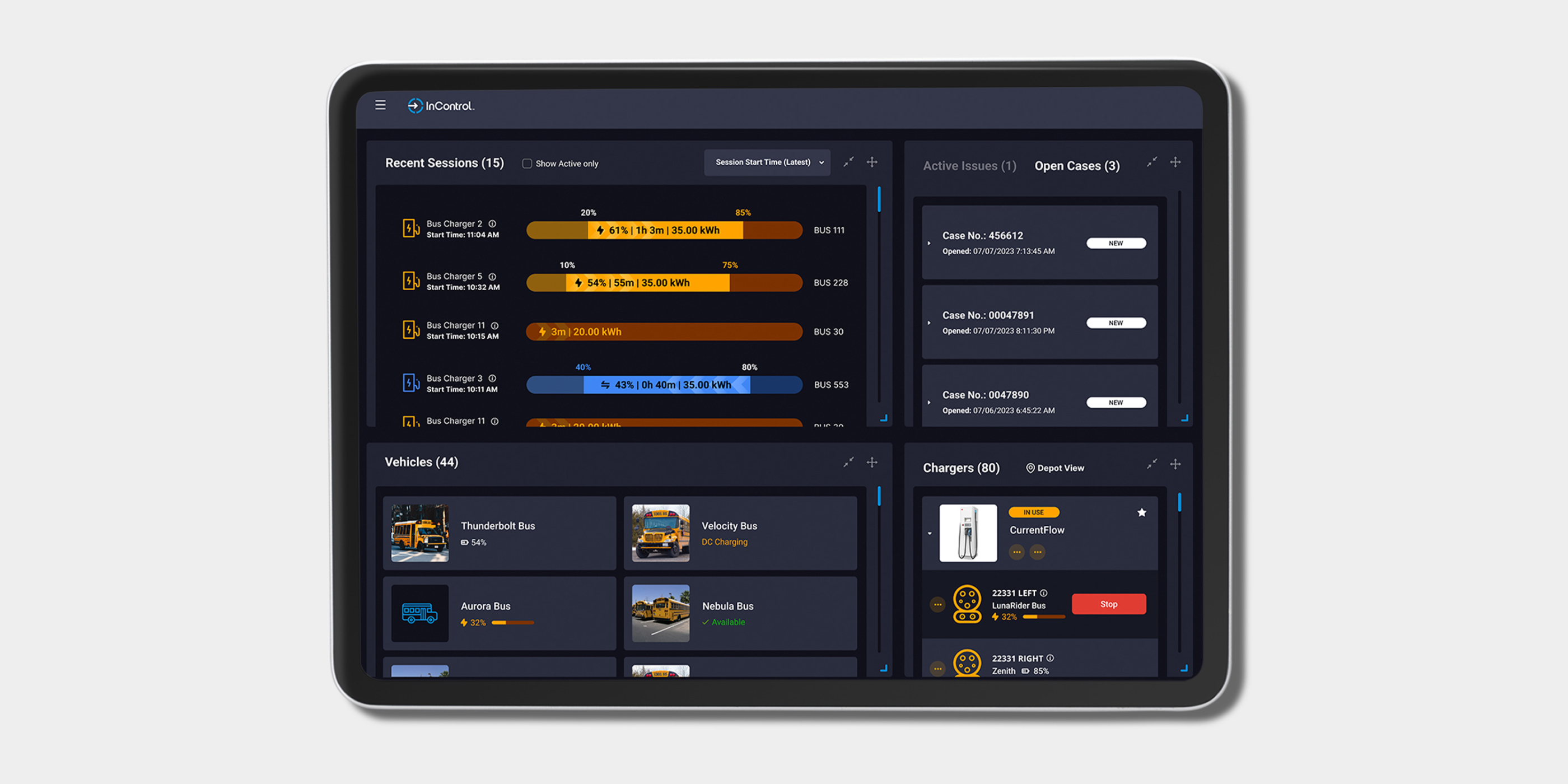

Watching users interact with the software in their actual work environments revealed insights no user interview or survey could capture. I saw fleet managers checking charger status on tablets while walking outdoor depots in bright sunlight—leading to our decision to make dark mode the default interface. I observed operators frantically switching between multiple screens to answer the simple question "When will this vehicle be done charging?"—which drove development of our predictive completion algorithms. I noticed that while we obsessed over charger uptime metrics, our users cared primarily about their vehicles and whether they'd be ready for the next shift.

These observations, documented in the interface lessons throughout this page, became design principles that guided feature prioritization and UX decisions. The human-centered approach meant sometimes building features that seemed less technically impressive but solved real operational pain points. It meant ruthlessly simplifying interfaces to work on a tablet screen. It meant surfacing vehicle data prominently while relegating charger diagnostics to secondary screens—counterintuitive for a charging management platform, but exactly what users needed.

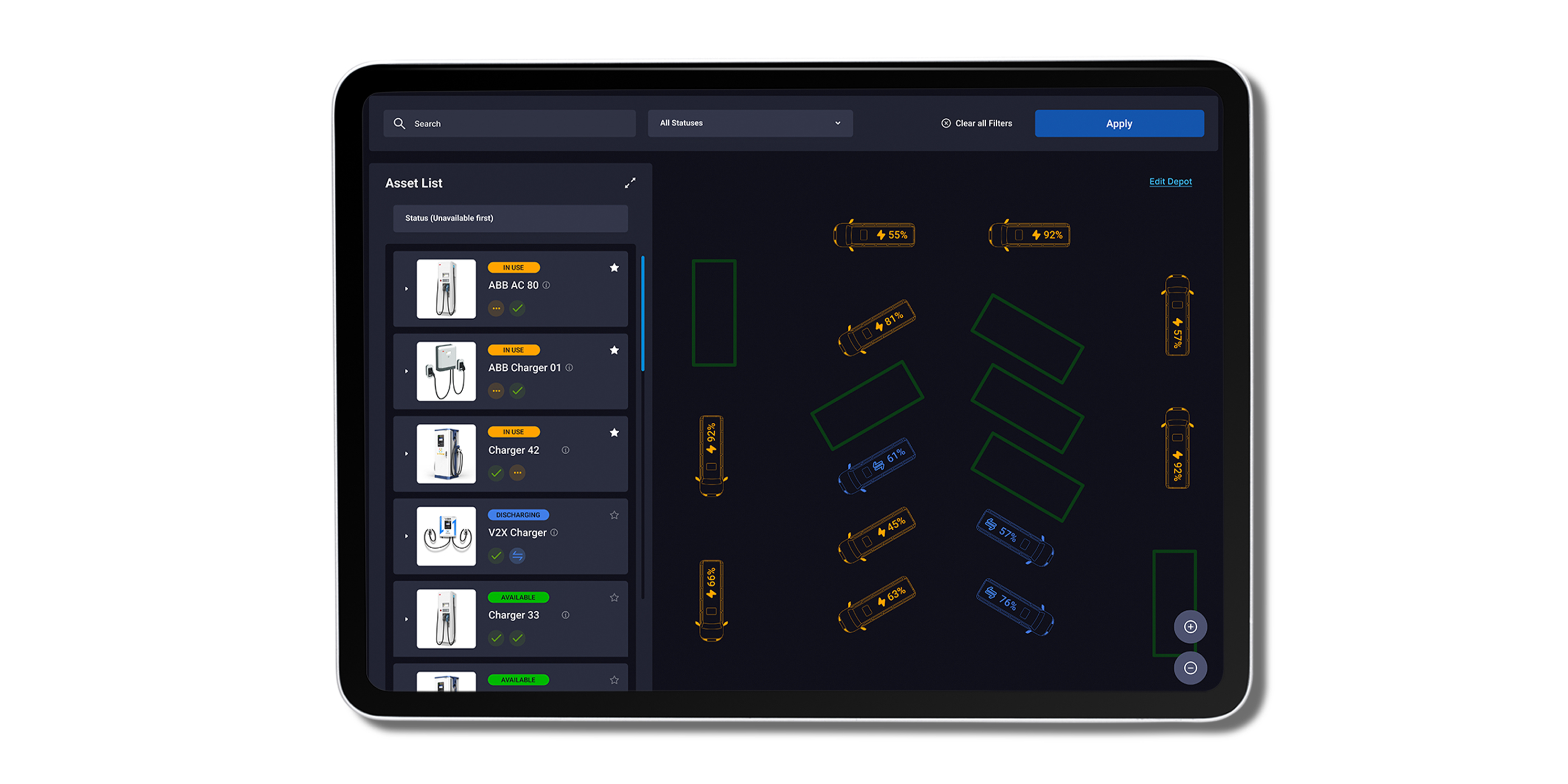

Depot View: Pioneering Spatial Visualization

One of the most significant innovations to emerge from this field-research approach was Depot View, an interactive spatial representation of charging infrastructure that became an industry first. InCharge's position as both hardware manufacturer and site builder meant we possessed detailed facility schematics for every depot we'd constructed. During site visits, I noticed operators mentally mapping charger locations when troubleshooting issues or planning vehicle assignments—they thought spatially, not in abstract lists.

The product insight was straightforward: why not visualize the charging infrastructure exactly as it existed in physical space? Working with our design and engineering teams, I led development of an interactive depot map that showed real-time charger status, vehicle positions, and session progress overlaid on actual facility layouts. Operators could instantly see which chargers were available, where problematic units were located, and how to optimize vehicle placement—all in a single, intuitive interface that matched their mental model of the site.

Depot View launched as the first spatial visualization tool in the charging management industry. The feature resonated so strongly with fleet-focused customers that competitors Synop and Flipturn have since developed similar capabilities for their platforms—validation that the human-centered research approach identified a genuine market need. For InControl, it became a signature feature that differentiated our platform and demonstrated deep understanding of fleet operations.

Data as a Product: Enabling Advanced Analytics and Machine Learning

Beyond building features for direct user interaction, part of my product management role involved treating data itself as a strategic product offering. I led initiatives to architect data pipelines that would enable both internal innovation and customer-driven analytics.

Power BI Integration and Data Warehousing: Recognizing that many enterprise customers wanted to incorporate charging data into their broader business intelligence ecosystems, I drove development of robust data export capabilities and native Power BI integration. This wasn't simply about providing API access—it required designing data schemas that made sense for analytical workloads, building reliable ETL pipelines, and ensuring data quality and consistency across the diverse hardware we supported. Customers now leverage InControl data for everything from executive dashboards to operational planning, analyzing trends that span charging, fleet utilization, energy costs, and maintenance patterns.

Predictive Maintenance and Machine Learning: The comprehensive data InControl collected—charger performance metrics, fault codes, environmental conditions, usage patterns, and service histories across thousands of charging sessions—created opportunities for machine learning applications. I worked with our engineering and data science teams to develop predictive maintenance models that could identify chargers likely to fail before they actually went offline. These models, trained on our multi-manufacturer dataset, could detect subtle degradation patterns that human operators would miss, enabling proactive service interventions that minimized downtime and reduced emergency repair costs. The ML capabilities became a key differentiator for InControl, showcasing how our manufacturer-agnostic approach generated unique data advantages.

Accelerating Innovation: AI-Assisted Product Development

As product manager, I'm always searching for ways to reduce time-to-market while maintaining quality. The emergence of AI-powered design and prototyping tools created opportunities to compress development cycles and iterate faster on new features.

Rapid Prototyping with AI Tools: I incorporated AI-based prototyping platforms into our product development workflow, using them to quickly generate interface mockups, explore alternative UX approaches, and test design concepts before committing engineering resources. This allowed us to experiment more boldly—creating multiple design variations for user testing, rapidly iterating based on feedback, and validating assumptions before development began. Features that might have taken weeks to prototype and validate could now move from concept to tested design in days.

Accelerated Feature Delivery: The combination of AI-assisted prototyping, strong API architecture, and cloud-native infrastructure enabled remarkable development velocity. We could conceive a feature based on field research, prototype multiple approaches using AI tools, validate with customers, and ship production-ready functionality in timeframes that would have been impossible with traditional development processes. This acceleration was crucial in a rapidly evolving industry where being first to market with capabilities like Depot View or predictive maintenance created competitive advantages.

Industry Recognition: Speaking at ACT Expo

The capabilities developed in InControl have gained recognition beyond our customer base. I've had the opportunity to present at ACT Expo, North America's largest advanced transportation technology and clean fleet conference, sharing insights on charging management systems and their role in fleet electrification.

ACT Expo 2024: "Reducing Complexity and Cost with Charge Management Systems"

As fleet operators grapple with multi-manufacturer charging infrastructure, I presented on how modern charge management systems reduce operational complexity and total cost of ownership. The session explored how platform-agnostic CMS approaches enable operators to manage diverse hardware through unified interfaces while maintaining manufacturer support relationships.

ACT Expo 2023: "Software & the Microgrid - Microgrids and Nonutility Strategies for Fleet Electrification"

Participated in a panel discussion on grid integration challenges, presenting how InControl's energy management capabilities help fleet operators optimize charging schedules, reduce demand charges, and work around slow utility circuit installations through intelligent load management and microgrid integration.

Both sessions included panel discussions with industry experts and audience Q&A, addressing real-world challenges facing fleet electrification efforts.

The New Paradigm: Charge Maintenance & Management System

Today, InControl stands as a true Charge Maintenance & Management System, a designation that reflects its expanded scope and universal applicability. The platform now serves as the operational backbone for charging infrastructure operators who refuse to be locked into vendor-specific ecosystems.

Unified Visibility Across All Hardware

InControl provides a single pane of glass for charging operations, regardless of what brands populate the site. Whether managing Tritium, ABB, ChargePoint, EVBox, BTC Power, or any combination of manufacturers, operators gain consistent visibility into performance metrics, utilization patterns, and system health. Real-time dashboards surface critical KPIs—uptime percentage, energy throughput, session data, and revenue metrics—normalized across hardware platforms for meaningful comparison and analysis.

Proactive, Intelligent Maintenance

The system's predictive maintenance algorithms analyze performance data across the entire installed base, identifying degradation patterns and potential failures before they result in downtime. When issues are detected, InControl automatically generates service tickets, sources the correct parts from a centralized inventory system that spans multiple manufacturers, and dispatches qualified technicians with the specific expertise required for each hardware platform.

The introduction of preventative maintenance contracts and scheduled service visits transforms reactive repair operations into proactive asset management programs, extending charger lifespans and dramatically reducing unexpected failures.

Optimized Service Delivery

InCharge Energy's service organization has evolved alongside the platform. Technicians are now trained and certified across multiple charging platforms, equipped with comprehensive parts inventories, and supported by InControl's diagnostic tools that provide step-by-step repair guidance regardless of charger brand.

The comprehensive service call tracking system ensures accountability and continuous improvement, while warranty tracking capabilities ensure that manufacturers remain responsible for their hardware commitments even within a multi-vendor environment. Maintenance Mode functionality allows service teams to work efficiently without creating false urgency or corrupting performance data.

This creates a service experience that's faster, more reliable, and more cost-effective than coordinating multiple vendor relationships.

Business Intelligence for Strategic Planning

Beyond day-to-day operations, InControl delivers sophisticated analytics that inform strategic decisions. Site planners can compare performance metrics across manufacturers to guide future procurement decisions. Energy managers can leverage patented smart charging algorithms to optimize charging schedules and reduce demand charges across mixed hardware deployments. Executive dashboards provide portfolio-level insights that were previously impossible to aggregate from disparate systems.

The Competitive Advantage: Why Agnostic Matters

The transformation of InControl from a proprietary platform to a universal Charge Maintenance & Management System represents more than technical evolution—it reflects a fundamental understanding of how the charging industry actually works. In a market characterized by rapid hardware innovation, multiple use cases requiring different charging solutions, and the inevitable reality of legacy equipment, vendor lock-in isn't just inconvenient—it's operationally and financially untenable.

By focusing on servicing chargers from every manufacturer, InCharge Energy has positioned InControl as the neutral infrastructure layer that the industry needs. Operators can make hardware decisions based on the best technical and economic fit for each specific application, confident that their management and maintenance infrastructure will remain consistent and capable regardless of brand choices.

This approach also future-proofs charging operations. As new manufacturers enter the market and technology continues to evolve, InControl's open standards support (OCPP 1.6-J and 2.0.1), API-first architecture, and cloud-native scalability ensure that operators can integrate new hardware without replacing their operational backbone or retraining their teams on yet another management platform.

The platform's reliability—maintaining over 99.9% uptime while scaling to 9x the infrastructure—provides the operational confidence that enterprise customers demand. When your business depends on charging availability, platform stability isn't a feature; it's a fundamental requirement.

Looking Forward: The Future of Charging Infrastructure Management

The evolution of InControl isn't finished. As the platform continues to develop, InCharge Energy is focused on expanding capabilities that leverage the unique advantages of cross-manufacturer visibility:

- AI-powered optimization that can automate repairs, charger control operations, predict failures ahead of time, and set dynamic charging schedules for specific use cases based on real performance data across brands

- Enhanced smart charging capabilities building on the company's patent-pending technology to deliver even more sophisticated load management, cost optimization, and vehicle charge scheduling

- Automated warranty and service contract management that tracks coverage across multiple vendors and ensures optimal use of manufacturer support

- Predictive parts procurement that anticipates maintenance needs across diverse hardware portfolios, reducing inventory costs while ensuring parts availability

- Industry benchmarking that allows operators to compare their performance against anonymized peer data across the entire charging ecosystem

- Expanded API capabilities that give partners even more powerful tools for building custom solutions on InControl's infrastructure

Conclusion: Management Without Borders

The InControl Charge Maintenance & Management System represents what infrastructure management should be in a mature, multi-vendor industry: capable, agnostic, and focused relentlessly on operational excellence rather than hardware loyalty.

Built on a foundation of open standards, guided by an API-first philosophy, and powered by cloud-native architecture, InControl has scaled from a single-vendor operations platform to the industry's most comprehensive multi-manufacturer management system—all while maintaining the reliability and performance that enterprise operations demand.

The vision of Sergey Ahranovich, Krishna Vanka, and Eugene Astapovich—to create a platform that embraces interoperability and puts operator needs above vendor loyalty—has been fully realized. Their architectural decisions, from OCPP support to API-first design to cloud-native infrastructure, have enabled InControl to grow 9x while maintaining over 99.9% uptime, supporting partners through robust programmatic access, and continuously innovating with patented technologies that solve real operational challenges.

By embracing the complexity of the real-world charging landscape and building a platform that turns that complexity into competitive advantage, InCharge Energy has redefined what operators should expect from their management infrastructure.

In an industry still finding its footing, InControl offers something rare and valuable: the freedom to choose the best hardware for every application, backed by the consistency of unified management, the confidence of expert manufacturer-agnostic service delivery, and the reliability of enterprise-grade infrastructure. That's not just platform evolution—it's an operational philosophy built for the long-term reality of charging infrastructure management.